We are dedicated to producing the best possible results for you.

One way which we do this is to produce digitising to suit specific fabrics. This is one reason why we need to know prior to digitising what the target item will be.

With most woven garments the surface of the fabric is fairly flat, and has no tendency to close over the top of the embroidery. With fleece, towelling and some knitted items like cable knit beanies, the embroidery stitches compress the fabric being sewn, and the result is two side effects.

-

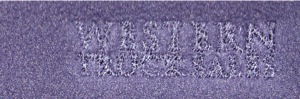

•Show through. This is where the pile of the fleece or towelling pokes through the stitches and leaves an unfinished or "not enough stitches' appearance to an embroidery.

-

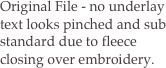

•Edge trapping. This is where the boundary between the unsewn edge and the embroidery results in the fleece or towelling closing over the top of the embroidery, resulting in pinched or thin looking lettering and detail.

You may have heard of a process involving glad wrap or cling film being used to "fix" this problem with your present embroiderer. This method does not require any alteration to the digitising file, or any additional stitches, which would appear to be one reason for using this method.

While this can assist with show through, by holding the fleece or pile under a layer of film that is more likely to be held in place by the embroidery stitches, this does nothing to prevent edge trapping.

In addition to this, the removal of the cling film can also leave unsightly residues at the edges if it is not removed cleanly and completely.

We have developed our own process to deal with both of these issues, which we call "Underlay". This sometimes confuses customers where they have a different understanding of underlay with embroidery, so we will illustrate our definition here.

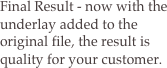

By laying down a cross hatch pattern of garment coloured stitches, slightly past the edge of the image to be seen, we tie down the pile and provide a flattened area for the subsequent embroidery to be sewn. This does add stitches to the process, and thus some additional cost. In the example above, less than $1.00 more and the result is something you and your customers can be proud of!

Should you have a budget conscious customer who does not want to invest the extra, we can always run a non-underlay file for you. we would stress that the result will not be the best possible and urge you to reconsider.

We do believe that the end justifies the means, as not only does this eliminate show through, it also compensates for edge trapping, resulting in that "perfect" finish we aim for with all our work. We are yet to be shown an alternative method that is superior in finish, so we continue to recommend this for maintaining a high quality product for your customers.

Monday, 10 August 2009